Intelligent Automated Optical Inspection

We built an algorithm that can classify the defeat of the objects on the assembling line.

- Background

- Initial Goal

- Our Contributions

Background

We want to make the assembling line more attractive, more fancy.

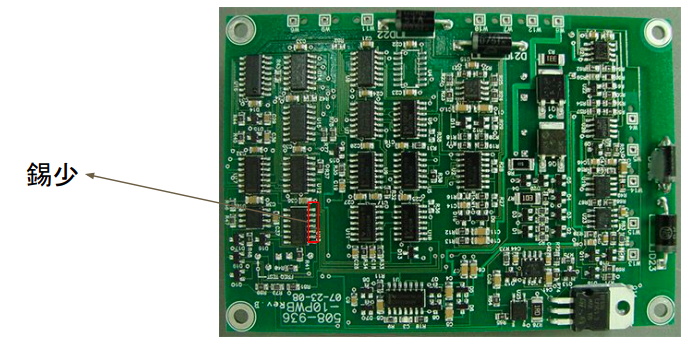

The AOI machine can generate some result of both catastrophic failure (e.g. missing component) and quality defects (e.g. fillet size or shape or component skew).

However, it need human to re-check, and The engineer has to learn from an experienced teacher.

Initial Goal

Transfer Learning

Decide a backbone of the learning model (e.g. ResNet50, VGG19, ...).

Transfer learning from other image data set (e.g. ImageNet, CIFAR100, ...).

And then fine tune with real data.

Few-Shot Learning

Survey multi-task learning and then build models to validate the idea.

Traditional Method & Some Pre-Processing

Traditional method like feature extraction and some classifiers.

Also, some pre-processing is needed.

Our Contributions

We use Mobile net pre-trained on ImageNet to perform transfer learning.

We have got an outstanding performance (96.5% and 100%) on 錫少(Too little tin) and 錫多(Too much tin) data type.

We also performe t-SNE analysis on the outputs of the trained model, and then we can visualize and observe the distribution of clustered data.

Contact us

We’d love to chat about this project, send us an email.